Professional Injection Molding Manufacturer since 2013-Fox Mold

Our Injection Molding reduces costs, improves efficiency, saves energy, promotes sustainability, and meets certification approvals.

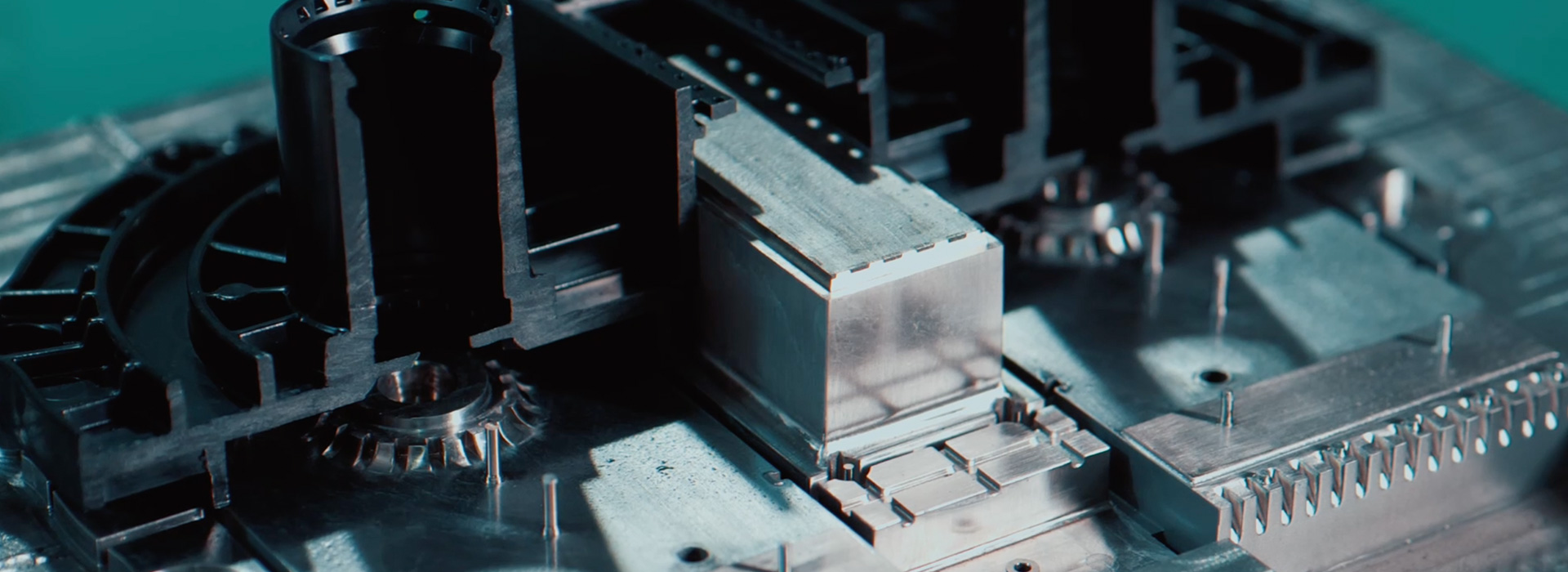

1. Precision manufacturing: Injection mold parts are manufactured to precise specifications for optimal performance and durability.

2. High-quality material: Plastic injection parts are made with precision and attention to detail, ensuring top-notch quality and performance.

3. Versatility: Overmolding parts offer a wide range of applications, making them suitable for various industries and products.

4. Durable: Metal insert molds are known for their long-lasting and sturdy construction, providing a reliable solution for various manufacturing needs.

5. Efficient production: LSR molds are manufactured with an efficient process to meet high demand and strict deadlines.

Fox Mold offers high-quality Injection Mold Parts, LSR Injection Mold, and Die Casting Parts.

Fox Mold Manufacturer

Our Mission Is Win-Win Cooperation.