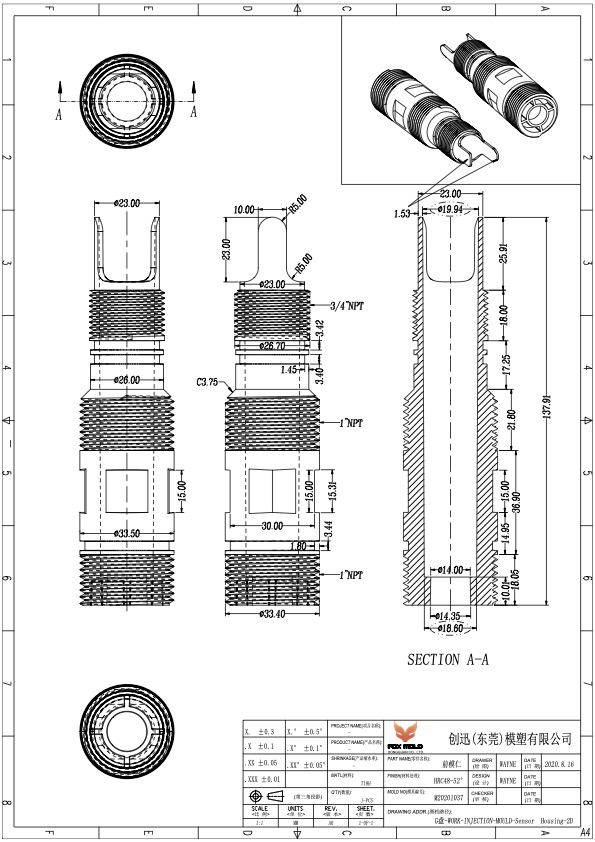

Low/high Volume Plastic Injection Molding service

Plastic injection molding service is a manufacturing process where molten plastic is injected under high pressure into a mold cavity, cooled, and solidified to form complex shapes. With ten years experience under our belt and good reputation from our clients, we work out cost-effective custom plastic molding solution from design, tooling, production, surface treatment, and assembly.

Our engineers have been in the custom plastic injection molding industry for over ten years. And 50 plus advance machines are in operation. Combining DFM and quality management system, the tolerance and lead time are sure to match and exceed your expectations.

Rich home solutions

High Quality plastic injection molding Process

Custom plastic injection molding service offers cost-effectiveness and precision which suitable for mass-producing items like and electronics enclosures, automotive parts and consumer goods etc,. With capabilities for customization, it supports various plastic materials, ensuring tight tolerances and consistent quality.

Choose Fox Mold, we promise to do everything needed to ensure a successful and satisfactory working partnership.

no data

Plastic Injection Molding Materials

P20, 718 and SKD61 are part of the materials we use for plastic injection mold tooling. Some of other accessible materials are:

PPO / HDPE / CPVC / PET / PVC

From prototype development to high-volume runs, plastic injection molding services streamline production which reducing waste and enhancing efficiency in the manufacturing sector.

As a professional plastic injection molding manufacturer, Fox Mold have the technology and equipment to handle all commercially available plastics (thermoplastic and thermosetting), contact us and we are happy to help you. Whether you need plastic injection parts for automotive, aerospace or medical, we can provide customized services

Get in touch with us

We provide design assistance to find the material in line with your needs and within your budget. With a strong local supply chain, we save you time and energy finding another supplier for your next procedure.