Product details of the injection mold parts manufacturer

Product Information

Fox Mold injection mold parts manufacturer is manufactured by the whole team with outstanding manufacturing capabilities. The product has passed the strict quality inspection of the authoritative third parties. Our injection mold parts manufacturer are all produced with exquisite quality.

The process from product design to mass production is a systematic, step-by-step, rigorous and complicated process. It needs to take into account market prospects, product functions, production costs, user groups, consumer demand and other aspects. Each link must be handled in detail to ensure the efficiency and quality of product development.

Project Overview

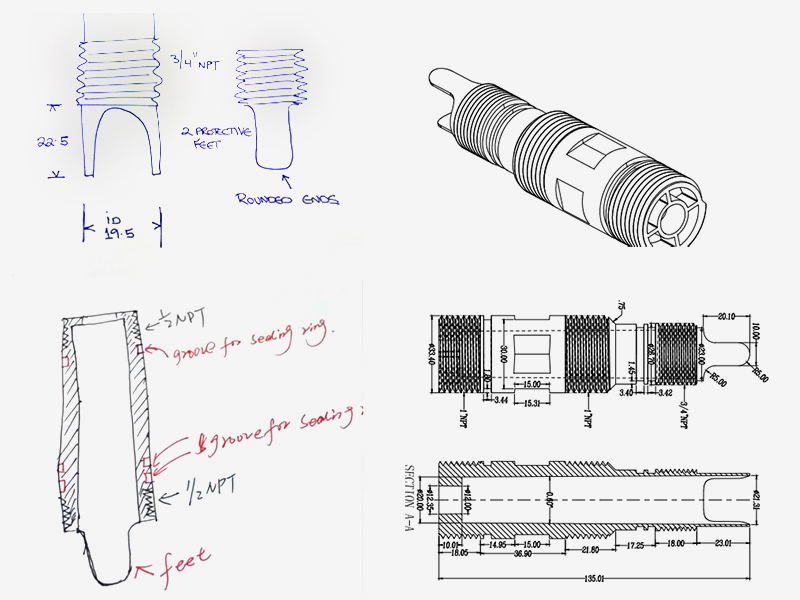

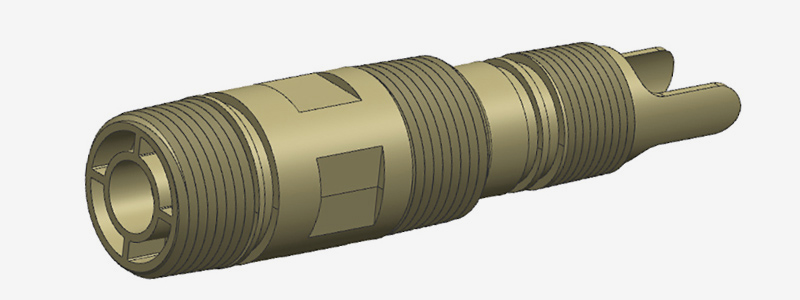

Our client only provided concept and draft as picture on left. Fox Mold acceptt the task to draw the part 2D and 3D, make 3D printing prototype - produce injection mold and molding plastic parts.

Project Timeline/Project Address:

March 2022/Dongguan, Guangdong. China

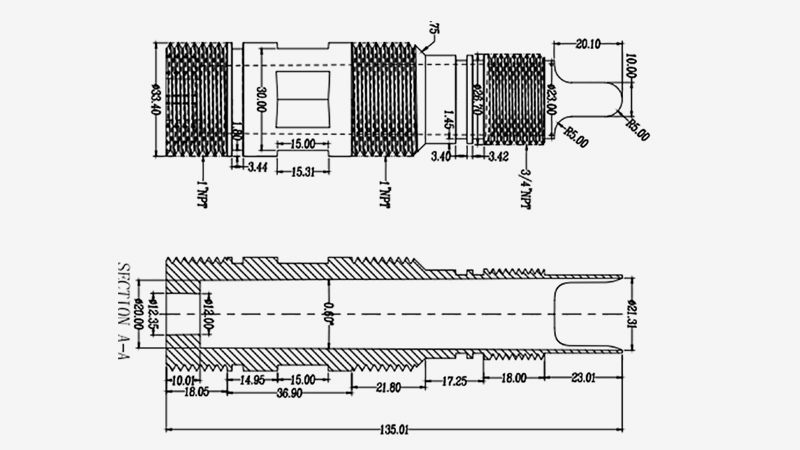

Part 2D drawing and 3D design drew according to draft or concept

We offer a one stop service with rich experience after getting know well client's concept by email, or video conference, which is the fastest way to talk face to face, client show us the draft trough shared window, we discuss the part application, usage environment, know about the assembly, we will recommend suitable plastic raw material, surface treatment. Then we draw the part 2D and 3D according to draft and all info collected from client. 2D format is usually DWG, PDF, 3D format is STP.

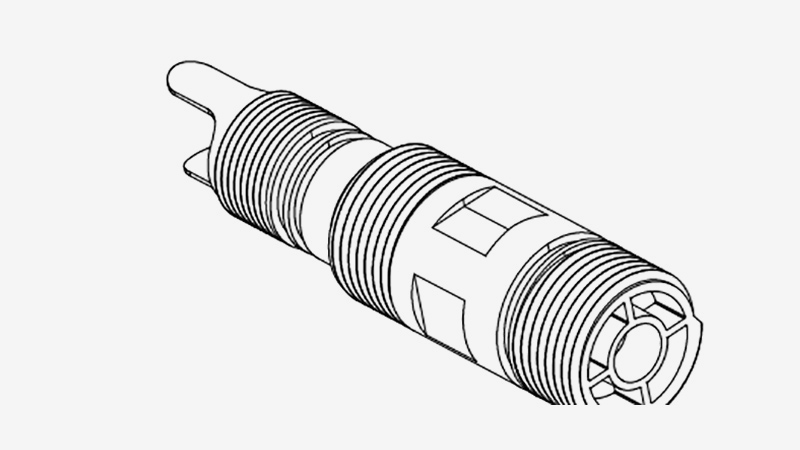

Prototype producing and assembly checking

When 2D is done, we send to client to get a release, and suggest client to produce prototype in local or by us, processing way including 3D printing, vacuum casting or CNC machining, even prototype injection mold, the decision is made after considering part precision, cost and lead time. For more detail of all prototype processing, please refer our FAQ No.16.

Prototype Revision 1 or 2 will be checked here at Fox Mold for assembled well before shipping to customer, to save client's time, after informing client all the adjustment and get their release, we will do the minor adjustment on next revision prototype and drawing. Well fitted prototype will be shipped to client to get design final check or market promotion to get bulk production order.

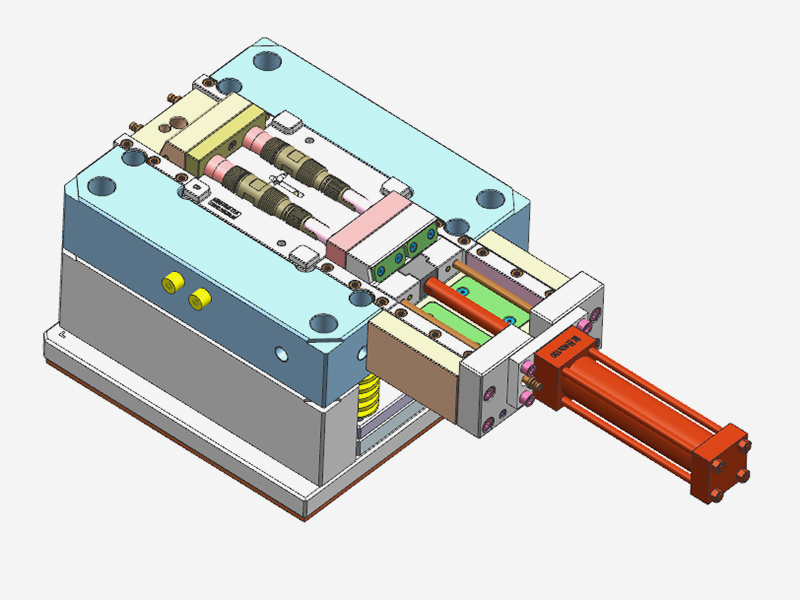

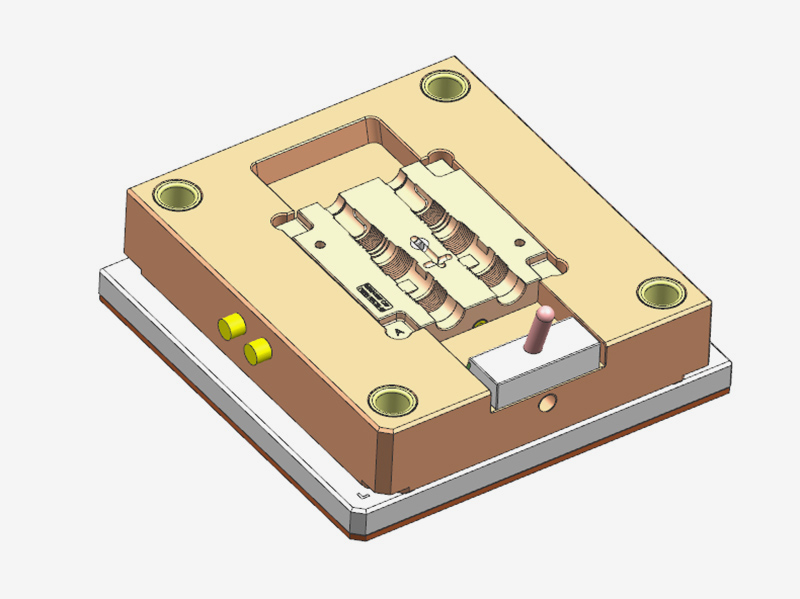

Mold designing and development

The Step 3 is to design and develop injection molds: DFM or Mold flow will be provided for primary study on mold design, mold 3D will be done after client approving DFM and MF, it usually take 3~5 days.

Finished injection mold and FAI measurement report.

10 sets of T1(the first mold test) injection molding sample will ship to client after first mold test. After client approve all samples. we produce parts in batches according client's demand. Or you can transfer the molds to local molding facility to save shipping cost of future part production

In this case, we developed 2 cavities injection mold according to volume customer needs.

Assembly sealing ring, metal insert and surface treatment.

When there are few geometries need to assembled together in one project, including liquid silicone rubber sealing ring, or metal components; we can produce all these parts for you in home. In this case we can check the fitment of all geometries and do further minor adjustment before shipping. To save your time of communication or shipping.

Part surface treatment like painting, silk printing, ultrasonic welding will be done by our supplier. You just need to send us AI drawing of surface treatment requirement.

Company Advantage

• The excellent quality of our company's products brings a wide range of customers sources and has attracted a large number of customers from overseas to purchase.

• Fox Mold is located in a position with traffic convenience. And the advantageous geographic location creates a broad prospect for the business development of our company.

• Since the beginning in our company has accumulated a large amount of production experience after the development for years.

• We take the quantitative business and personalized service as the standard, and consider the needs of customers as the guide to provide consumers with intimate services.

Dear customer, if you have any questions about Fox Mold's Injection Mold Parts,LSR Injection Mold,Die Casting Parts, please call us. We will sincerely reply with an answer to your question and provide you with professional services.