Soft Tooling for Injection Molding Directly Sale

Product details of the soft tooling for injection molding

Product Description

Proved in practice, soft tooling for injection molding has reliable shape, reasonable structure and excellent quality. The products have passed strict quality examination and inspection before they leave the factory. Loaded with all these features, this product is more popular than other ones.

Energy Storage Management System, which is widely used in power grid peak regulation electric transportation and distributed energy. Lithium-ion battery PACK, also known as battery module, is a lithium-ion battery manufacturing process. It refers to connecting multiple lithium-ion single cell groups in parallel and series to form a specific shape according to customer requirements. The important parts of the battery PACK include single battery modules, electrical systems, thermal management systems, cell carrier and BMS. Fox Mold is honor to be supplier of Cell carrier, to produce high accuracy cell carrier molds and parts of our client.

Project Overview and Connector Profile:

Fox mold's main supply was the mold and molding bulk parts to meet Alpha and Beta test asap. This bulkhead connector was CNC machining to verify part design and assemblied well with other geometries, the molded parts should be accurated and meet the time line.

Project Timeline/Project Address:

March 2021/Dongguan, GuangDong, China.

Injection mold/Injection molding service we offer:

Fox mold provided all the injection molds an injection molding parts for the client's mutiple ESS projects. In order to ensure the accuracy and time line, we invest lot of time to do Mold flow analysis with support of raw material supplier.

Challenge

This connector is more complex than ordinary plastic products, the product has a full-circle undercut design and has strict dimensional tolerance requirements, especially for the roundness and concentricity, easily distorted during demolding.

Solution

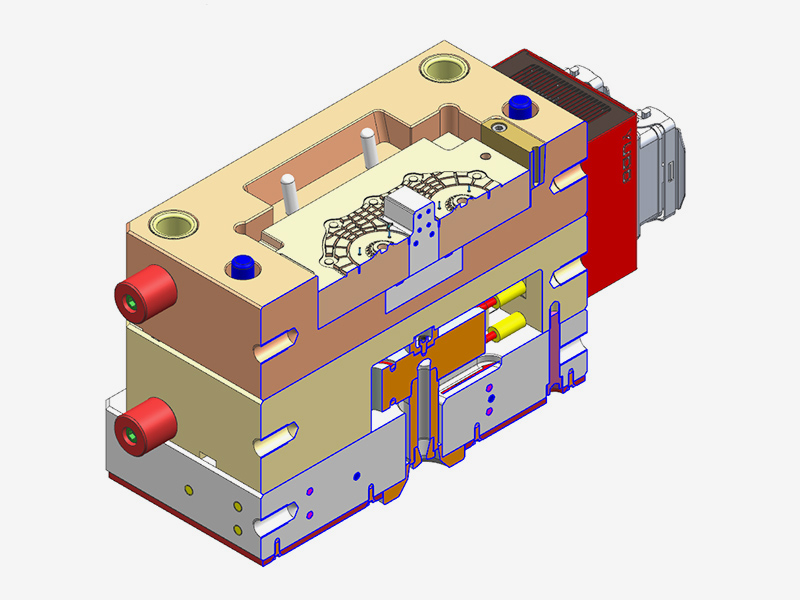

We did a comprehensive DFM analysis, mold flow analysis, and detailed mold 3D/2D design. three ingenious design of mold are included:

1. Multi-point valve hot runner glue injection solution, this hot runner design does not produce any runner, saving product costs.

2. Collapsabile core automatic demoulding structure is adopted to solve the problem of full-circle undercut demoulding issue and realize fully automatic production.

3. Conforming cooling system was designed to install on important dimension portion, this compliated cooling system was produced by metal 3D printing process and CNC machining. This sufficient cooling can ensure the roundness and concentricity tolerance of the product.

Final Completion

The mold was finally manufactured, FAI was released by 1 time, without any further modification or optimization on mold. Time line of Alpha and Beta low volume production and mass production was achieved to meet customer needs.

Application Scope:

Busbar tray, carrier and connectors

Service We offer:

Learing raw material. Doing mold flow analysis to review raw material with hot runner to predict part filling situation, get the best injection molding parameter, analysis mold sulution and optimize mold cost and molding cost. DFM and mold design, developing injection mold, doing mold trail, FAI measurment and support part mass production.

Company Advantage

• Fox Mold has an international sales channel. Injection Mold Parts,LSR Injection Mold,Die Casting Parts are mainly sold to some countries and regions in Europe, America, and Australia.

• Fox Mold extensively takes excellent talents in, so as to establish a management team with a good education background, high quality, and high efficiency. The team members are committed to leading the company to develop rapidly by adopting modern management concept.

• Our company has built a sound service system. It can provide customers with one-stop services with product consultation, professional debugging, skills training, after-sales service.

Hello, thanks for your attention to this site! If you are interested in our products or services, please contact us. It is an honor for Fox Mold to receive your call and cooperate with you.