Fox Mold as a professional injection molding manufacturer & suppleir which provides custom injection molding and die casting service since 2013.

Our custom injection molding solutions encompass every step of design, tooling, production, surface treatment, and assembly to deliver parts within 2 weeks.

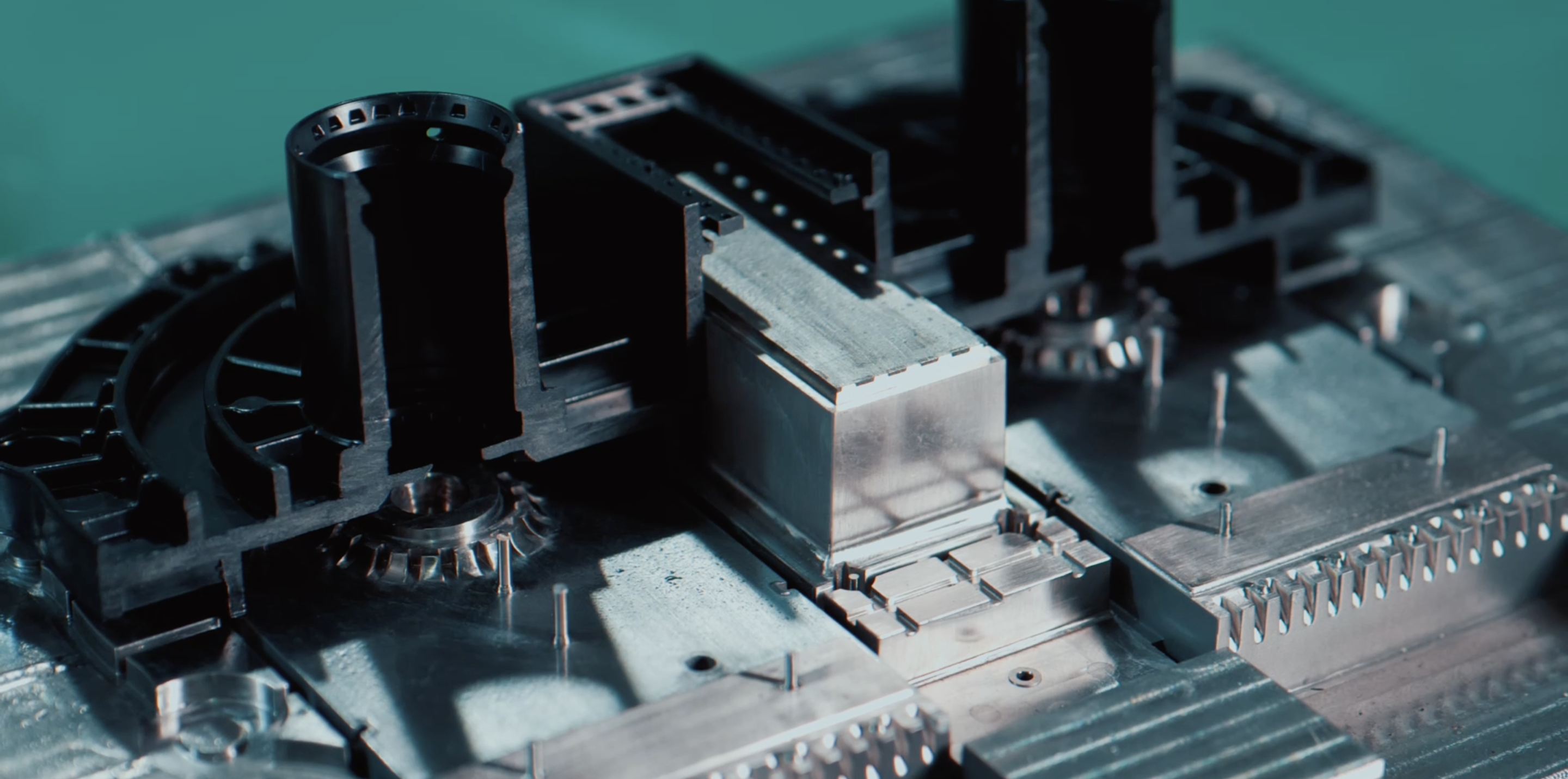

Our injection molding includes plastic injection molding, overmolding injection molding, metal insert injection molding. With our advanced technology and equipment, we can handle all commercially available plastics.

Added surface treatments increase corrosion resistance and durability while we ensure tight tolerance that matches your requirements.

Capable of handling complex shapes and forms, our pressure die casting delivers excellent molds made to last for long periods.

The surface of our molds is treated to ensure corrosion resistance and smoothness.

To accomplish excellent pressure die casting, we use a powerful MUD system for tooling that reduces the cost and time of the molding process.

Fox Mold has established its reputation as a Injection mold and custom injection molding production expert since its inception in 2013. We are home to over 15 experienced engineers who are uniquely attended to our clients' needs. 99% accurate delivery keeps us the most favorable in our clients' lists.

Our services range from rapid tooling, plastic injection molding, overmolding injection molding, die casting, liquid silicone rubber molding to surface treatment. Secondary processing includes free rework, free mold care, customized assembly and delivery.

We provide design assistance to find the material in line with your needs and within your budget. With a strong local supply chain, we save you time and energy finding another supplier for your next procedure.